Die casting, as is also commonly understood, is a process for producing engineered metal parts. The process entails forcing molten metal under questionable into steel molds or dies that are reusable. These dies might be designed to produce complex shapes which has a remarkable accuracy in addition to repeatability.

This method is favored by many industries today as a result of some its advantages over injection moulding china. It is usually asserted it creates sturdy and much more durable parts with closer tolerances. Furthermore, die cast parts have greater effectiveness against extreme temperature as well as have superior electrical properties.

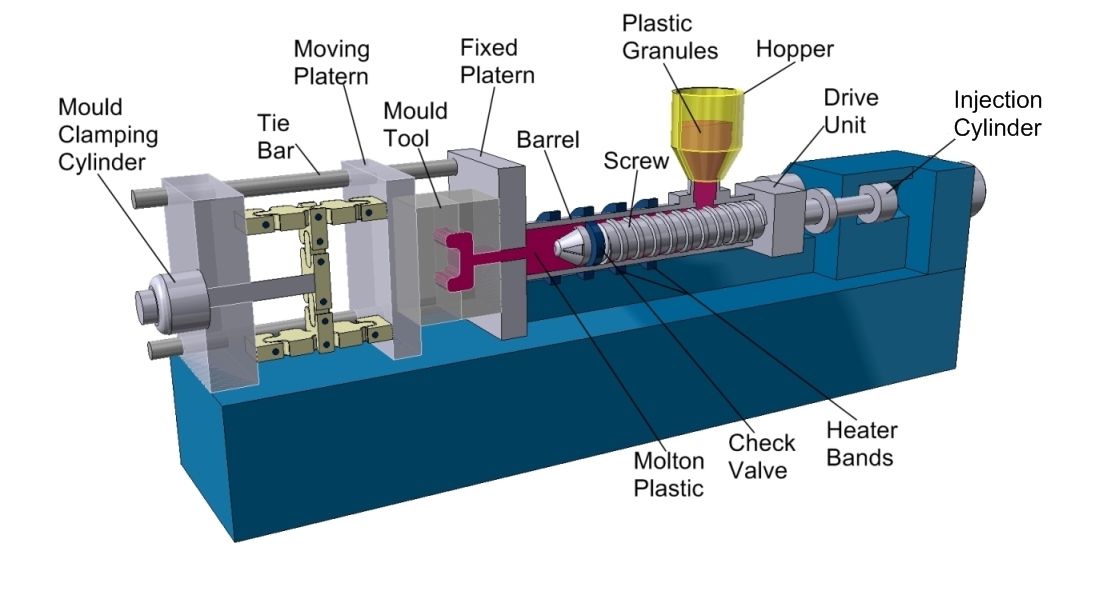

This method constitutes injecting molten plastic under questionable into a die or perhaps a mold. Die casting machines are usually rated in clamping tons, indicating the quantum of pressure they may be effective at exerting about the die.

There are 2 types of machines and their only basic difference will be the methods employed to inject molten plastic into a die Body carries a hot chamber and yet another flu chamber. A complete cycle may differ from below one second to 3 minutes with regards to the sized the specified product. Labeling will help you the fastest way of producing precise plastic or non-ferrous metal parts.

It has to be mentioned that it is an efficient, economical process offering a broader range of shapes and components than another manufacturing technique. The main element benefits might be summarized as: high-speed production capability /complex shapes within close tolerance limits/ guaranteed dimensional accuracy and stability/ finished products are heat resistant and sturdier than plastic injection moldings of similar dimensions / multiple finishing techniques/ end products can easily be plated or finished.

As to it is usually asserted die casting produces sturdier, tougher parts with closer tolerances. The construction of die casting dies is practically the same as those of molds for injection molding. Die cast parts have greater effectiveness against extreme temperature as well as have superior electrical properties. Compared with plastic injection moldings, die castings better assist in preventing radio frequency and electromagnetic emissions. For chrome plating, die castings less complicated more compatible than plastics.

There is absolutely no denying how the art work of reworking plastic resins into useful products or components has received an enormous affect commercial and industrial spheres. Injection molds is often rather expensive however, if the desired part quantity is large, the mold cost will become cost-effective in the end. Some molds are of course made out of multiple cavities; these multi-cavity mold contributes to increased production efficiency and the cost per part are considerably minimized.

Although a shot molding machine is a complex piece of equipment, it contains two basic elements, the injection unit and the clamping unit. Historically speaking, this technique was originally designed only depending on metal designs. Injection molding has gained plenty of popularity in an exceedingly brief time due to its own peculiar merits and it is advantages including minimal losses from scrap as scrap pieces might be melted and recycled. Injection molding has minimal finishing requirements and it is process fundamentally is different from metal die casting – molten metals can merely be poured whereas plastic resins have to be injected with force.

More details about injection moulding china check this website: read more